Medical imaging, diagnostics, and minimally invasive surgical technologies require optical components with exceptional precision, stability, and compact form factors. GENERAL OPTICS supports medical device manufacturers and research institutions with high-performance optical elements, endoscopic lens systems, and specialized diagnostic modules designed for accuracy, reliability, and long-term clinical performance.

Industry Challenges

Medical optical systems must meet demanding criteria:

- Miniaturized, high-resolution optical designs for endoscopy and micro-imaging

- Biocompatible and stable materials suitable for clinical environments

- High transmission and low aberration across VIS–NIR ranges

- Strict mechanical tolerances and parfocal consistency

- Reliability under repeated sterilization and environmental stress

GENERAL OPTICS excels in developing precision optics tailored to life-critical diagnostic and imaging systems.

Our Solutions

Endoscopic & Micro-Imaging Optics

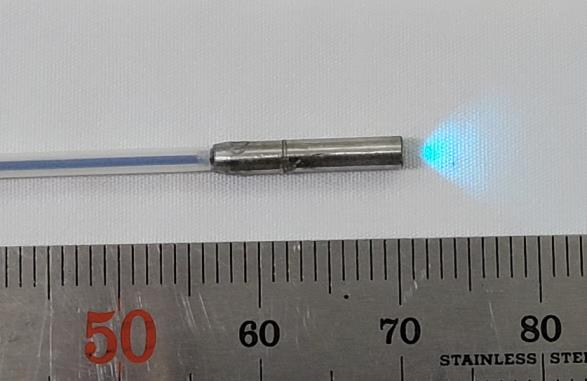

GENERAL OPTICS has extensive experience designing and manufacturing optical systems for medical endoscopy and micro-diagnostic probes.

Key capabilities include:

- Objective lens systems for endo-microscopy

- High-resolution imaging for early cancer detection (gastric & colorectal)

- Assembled probe-level lens designs with measured image quality

- Three registered patents related to the endoscopic lens system

Applications include:

- Gastrointestinal endoscopy

- Minimally invasive imaging

- Confocal / OCT micro-probes

- Surgical visualization

Multi-Modal Diagnostic Optical Systems

GENERAL OPTICS contributed to national R&D programs involving multi-modal optical diagnostic systems integrating:

- OCT (Optical Coherence Tomography)

- Confocal Microscopy (CM)

- AI-assisted Clinical Decision Support Systems (CDSS)

These systems support:

- Early cancer detection

- High-resolution tissue characterization

- Real-time imaging with enhanced diagnostic accuracy

This demonstrates GENERAL OPTICS’ capability in complex optical system design for next-generation medical diagnostics.

Compact Molded Optics for Medical Devices

GENERAL OPTICS develops:

- Injection-molded micro lenses

- Miniaturized optical structures for confined spaces such as probe tips

- Custom optical layouts for micro-imaging systems

These designs enable compact, lightweight, high-performance imaging modules for portable and disposable medical devices.

Manufacturing & Quality Advantages

Precision Fabrication for Clinical-Grade Optics

Medical-grade optics require extremely low aberrations, tight centration tolerances, and high surface quality.

GENERAL OPTICS ensures this through:

- Ultra-precision grinding & polishing

- Large set of polishing and centering machines

- Advanced aspheric and freeform metrology

Performance is evaluated with:

- Zygo interferometers

- Talysurf PGI aspheric profiler

- High-resolution tool microscopes

Advanced Coating Solutions for Medical Imaging

Coatings for medical systems must offer:

- High transmission

- Low reflectance

- Durable resistance to cleaning chemicals

GENERAL OPTICS supports this with:

- E-beam and Ion-Assisted Deposition (IAD)

- AR, HR, broadband AR, and protective coatings

- FT-IR and UV-Vis verification for spectral performance

Environmental Reliability Testing

Medical devices undergo frequent cleaning, sterilization, and environmental stress.

GENERAL OPTICS applies MIL-STD-based durability testing:

- Abrasion

- Adhesion

- Temperature & humidity cycling

- Solubility & cleanability

These tests ensure stable performance throughout the device’s clinical lifetime.

Why GENERAL OPTICS

- Proven success in national medical R&D projects

- Expertise in endoscopic and microscopic imaging optics

- Ability to design & manufacture miniaturized, high-performance lens systems

- Complete in-house production for secure and reliable delivery

- ISO 9001 & ISO 14001 certified quality systems

GENERAL OPTICS delivers precision optics that enable next-generation medical diagnostics, imaging, and minimally invasive procedures with improved clarity, reliability, and clinical value.