Machine vision, precision inspection, metrology, and infrared imaging systems rely heavily on optical components that deliver exceptional resolution, stability, and spectral performance. GENERAL OPTICS provides high-precision lenses, IR optics, and custom optical assemblies engineered to meet the demanding requirements of automated inspection and imaging platforms across semiconductor, electronics, medical, and industrial markets.

Industry Challenges

Machine vision and IR imaging systems require:

- High-resolution optics matched to modern high-pixel-density sensors

- Precise control of aberrations and distortion for accurate measurement

- Optimized transmission across visible and IR spectral ranges

- Mechanical and environmental stability for continuous operation

- Rigid quality standards for MTF, parfocal stability, and wavefront precision

GENERAL OPTICS supports these needs through advanced design, precision manufacturing, and in-house metrology systems.

Our Solutions

Precision Objective Lenses for Machine Vision

GENERAL OPTICS designs and manufactures objective lenses optimized for high-resolution inspection applications:

- 4X and 5X Objective Lens Series

- Maximum sensor format: 2/3”

- NA: 0.112 (4X) / 0.14 (5X)

- Working distance: 33–36 mm

- Parfocal length: 95 mm, measured δ ≈ 5 μm

These lenses deliver:

- High contrast and resolution

- Minimal distortion

- Stable parfocal performance across magnifications

Compatible tube lenses (F200) are also available for integrated system configurations.

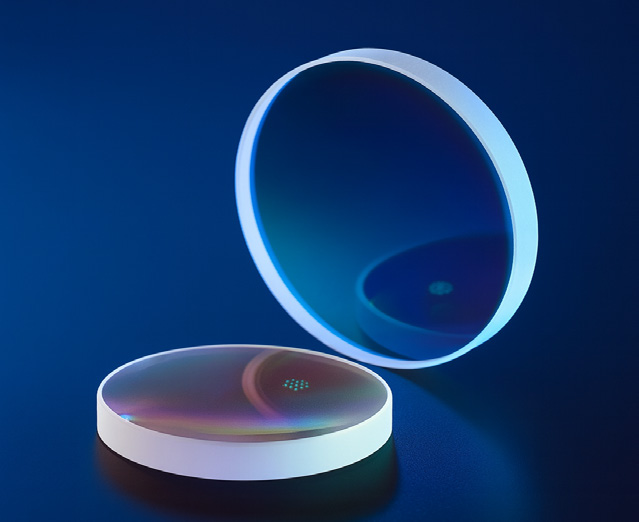

Imaging Components & Optical Elements

Machine vision systems demand optics that provide precision alignment, low scatter, and stable spectral characteristics.

GENERAL OPTICS offers:

- High-precision windows & mirrors

- Spherical, aspherical, cylindrical lenses

- Prisms and beam-steering elements

- Low-scatter IR-compatible optical components

These components support robust imaging performance across diverse industrial inspection platforms.

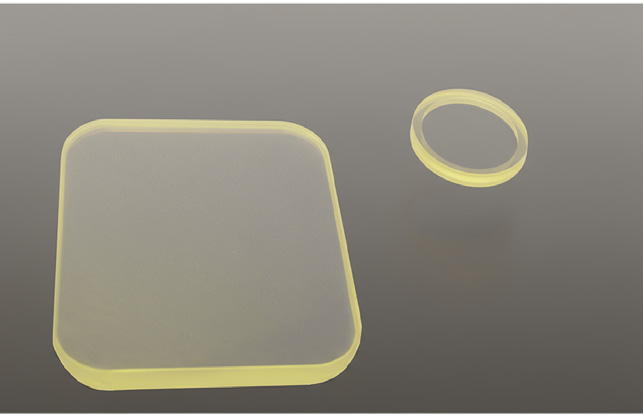

Infrared (IR) Optics

GENERAL OPTICS manufactures IR optical components suitable for:

- Thermal imaging

- Industrial inspection

- Security and monitoring systems

Capabilities include:

- Custom and standard IR lens elements

- High-durability IR coatings

- FT-IR-verified transmission characteristics (2,000–20,000 nm)

Manufacturing & Quality Advantages

Precision Metrology for Imaging Optics

To ensure the highest image quality, GENERAL OPTICS performs full optical characterization using:

- Zygo interferometers (4” & 15”) for wavefront measurement

- Talysurf PGI Optics for aspheric surface metrology

- Autocollimators & centering microscopes for alignment accuracy

- UV-Vis and FT-IR spectrophotometers for spectral calibration

These tools ensure MTF stability, parfocal accuracy, and spectral consistency required in advanced imaging platforms.

Advanced Coating Reliability

Imaging and IR optics require coatings with high transmission and long-term durability.

GENERAL OPTICS applies:

- E-beam and IAD coatings (End-Hall / RF-coil ion sources)

- Anti-reflection, protective, and spectral-optimized coatings

ll coatings undergo standardized MIL-STD durability tests to ensure reliability in continuous-operation environments.

Why GENERAL OPTICS

- Proven expertise in high-resolution imaging optics and IR components

- Complete in-house production: grinding → polishing → coating → testing

- Advanced metrology ensuring precision and repeatability

- High-performance optics for OEM machine vision and IR system manufacturers

- Certified quality systems (ISO 9001 & ISO 14001)

GENERAL OPTICS delivers stable, high-resolution optical components that empower next-generation machine vision and IR imaging applications.