Aerospace, defense, and security systems demand optical components that maintain absolute reliability in extreme environments. GENERAL OPTICS delivers mission-critical optical solutions for detection, monitoring, targeting, and environmental sensing applications by combining precision manufacturing with field-proven durability and advanced optical engineering.

Industry Challenges

Optics used in aerospace and defense applications must withstand:

- Extreme temperature, humidity, shock, and vibration

- Long-term exposure to harsh or contaminated environments

- High reliability requirements for mission-critical sensing

- Strict optical performance standards across visible, NIR, and IR bands

- Miniaturization needs for portable or embedded detection systems

GENERAL OPTICS provides optical systems engineered and validated to meet these demanding operational conditions.

Our Solutions

BioWatch Program

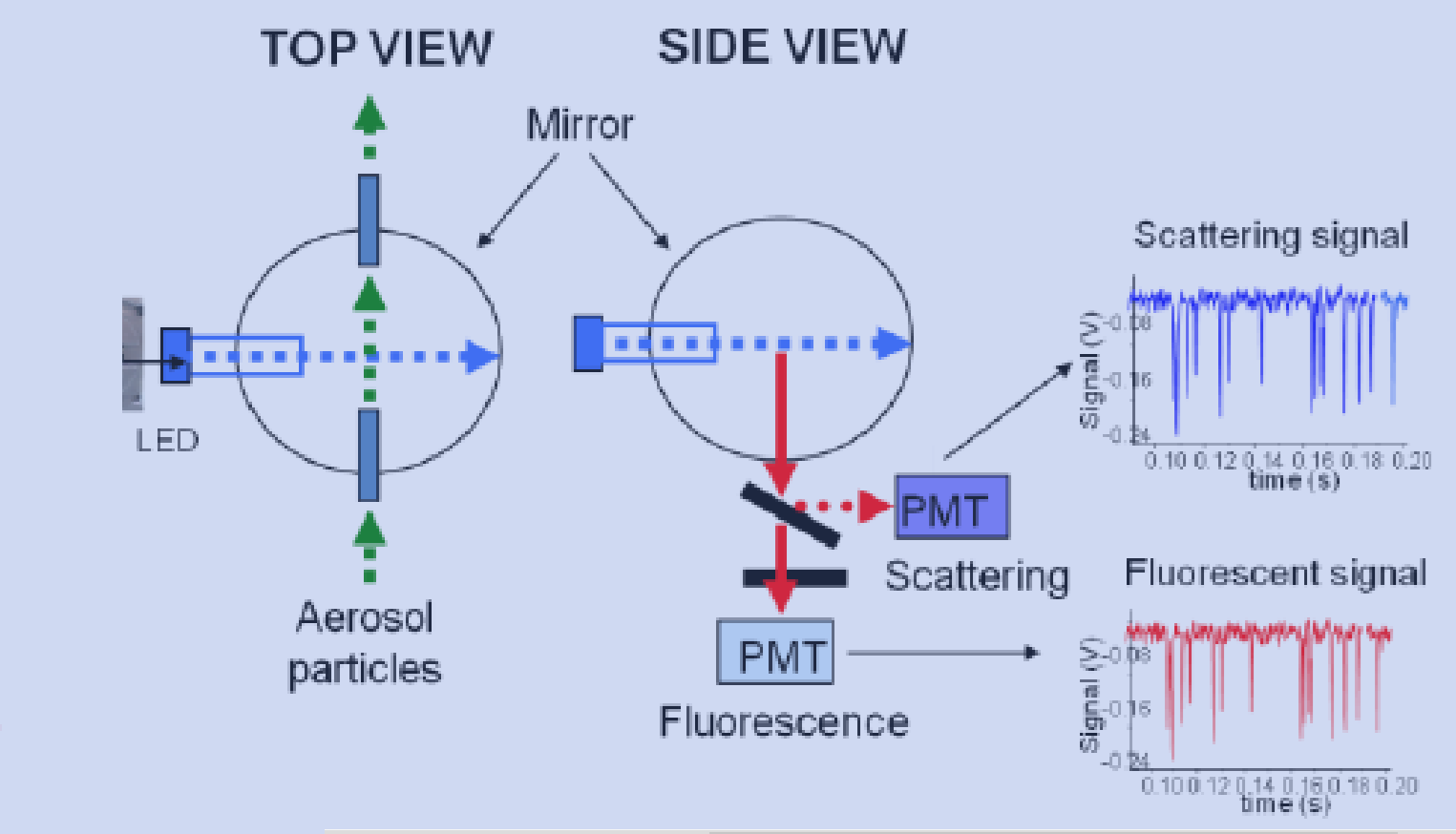

GENERAL OPTICS developed and manufactured optical detection modules capable of detecting biological threats.

Key achievements:

- Detection of biological particles in air

- Systems deployed during the PyeongChang Winter Olympics for real-time public safety monitoring

- Optical design covering scattering & fluorescence detection paths

Applications include:

- Environmental monitoring

- Biothreat early-warning systems

- Mobile and fixed security platforms

Optical Gas Detection Modules

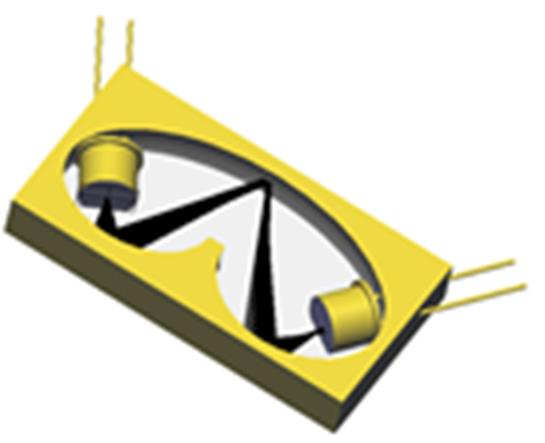

Through national R&D programs, GENERAL OPTICS developed compact gas-detection optics using wavelength-specific absorption measurement.

Capabilities:

- Miniaturized module (32 × 17 × 4.4 mm, Ø26.5 mm)

- Detects gases via characteristic absorption bands

- Robust, compact structure suitable for UAVs, mobile detectors, and field instrumentation

- Supported by patented optical cavity technologies

Applications:

- Hazardous gas monitoring

- Industrial safety systems

- Defense CBRN detection platforms

Plasma & Fusion Diagnostic Optical Systems

GENERAL OPTICS developed multiple optical modules for the fusion research reactor, demonstrating ultra-high-precision alignment and durability in harsh environments.

Developed systems include:

- Visible inspection optics

- MSE diagnostic optical system

- IR inspection optics

These systems operate in high-temperature, high-radiation fusion environments—validating GENERAL OPTICS’ capabilities for extreme operational conditions similar to those in aerospace and defense missions.

Manufacturing & Quality Advantages

Environmental & Reliability Testing

GENERAL OPTICS performs rigorous durability evaluations following MIL-STD procedures:

- Abrasion testing

- Adhesion testing

- Temperature cycling (−80°C to +90°C)

- Humidity testing (0–100%)

- Salt-fog corrosion tests

This ensures long-term stability required for airborne and defense-grade optics.

Advanced Coating Technologies

Defense applications require coatings with exceptional durability and spectral control.

GENERAL OPTICS operates large-format coating chambers (900Φ–2050Φ) with:

- E-beam evaporation

- IAD (Ion Assisted Deposition)

- End-Hall and RF-coil ion sources

These systems produce dense, adherent coatings suitable for:

- IR imaging systems

- Targeting and tracking optics

- Sensor windows exposed to harsh environments

Precision Metrology Infrastructure

To ensure optical integrity in mission-critical applications, GENERAL OPTICS employs:

- Zygo interferometers (4” & 15”)

- FT-IR & UV-Vis spectrophotometers

- Aspheric surface metrology (Talysurf PGI Optics)

- High-precision centering & alignment systems

This guarantees optical accuracy, wavefront stability, and spectral reliability for aerospace and defense programs.

Why GENERAL OPTICS

- Proven track record in national security & fusion research optics

- Ability to design and manufacture optics for high-risk, high-precision missions

- Full in-house production chain enabling secure, reliable development

- Compliance with international quality standards (ISO 9001, ISO 14001)

GENERAL OPTICS delivers durable, high-precision optical systems engineered for the complexity and criticality of aerospace and defense applications.