From flat to spherical, cylindrical, and prism optics — each geometry requires a unique and proven process.

At General Optics, these processes are not just steps in manufacturing; they are the reason we deliver consistent quality and reliability. Every procedure is designed to secure precision, minimize defects, and ensure long-term performance in the most demanding applications.

“Precision you can rely on”

Our systematic approach to fabrication means that no matter the shape or size of the optic, customers receive the same promise:

uncompromised accuracy and dependable results.

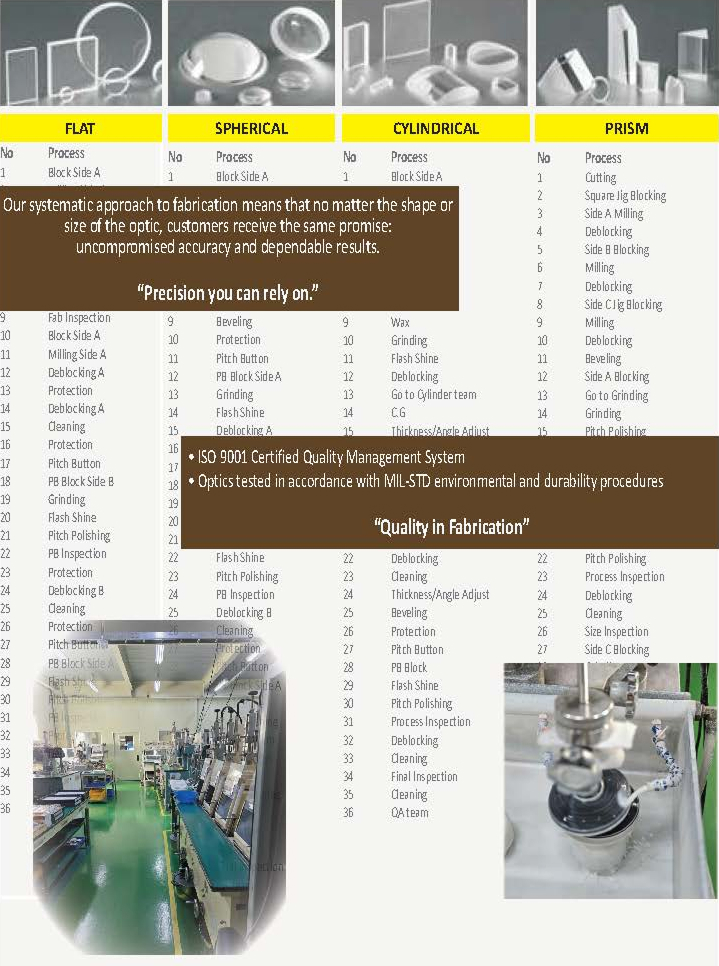

FLAT

| No | Process |

|---|---|

| 1 | Block Side A |

| 2 | Milling Side A |

SPHERICAL

| No | Process |

|---|---|

| 1 | Block Side A |

| 2 | Milling Side A |

CYLINDRICAL

| No | Process |

|---|---|

| 1 | Block Side A |

| 2 | Milling Side A |

PRISM

| No | Process |

|---|---|

| 1 | Cutting |

| 2 | Square Jig Blocking |

Quality in Fabrication

- ISO 9001 Certified Quality Management System

- Optics tested in accordance with MIL-STD environmental and durability procedures